- Aerated (AAC/ALC) Block Characteristics

- Difference Between AAC & ALC

- Difference between CLC and ALC

- Project Information - Is it worth starting

- ALC Manufacturing Process, Raw Material & Mix Ratios

- AAC Manufacturing process, Raw Material & Mix Ratios

- 10 Reasons to Choose Essarcon

- FAQ - Frequently Asked Questions

Characteristics of aerated lightweight concrete blocks

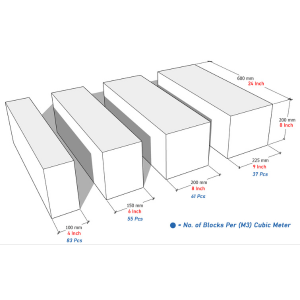

100 x 200 x 600 = 83 Pcs.

150 x 200 x 600 = 55 Pcs.

200 x 200 x 600 = 41 Pcs.

Thickness of wall = Thickness of block

| Characteristics of blocks : | Steam Curing - AAC | Natural Curing - ALC/NAAC |

|---|---|---|

| Density | 600-750 | 600-800 |

| Compressive strength required | 30+ Kg/cm² After 3 Days |

25+ Kg/cm² After 28 Days |

| Change in strength | No gain in strength in Future | Gain in strength Day by Day |

| Block shipment | Next Day | Can ship After 10 Days |

| Water absorption | 20-24% | 12-20% |

| Raw material | Water Cement Lime Gypsum Fly ash Aluminum powder Coal/Wood (for steam) |

Water Cement Lime Gypsum Fly ash Aluminum powder Supplementary additives (hardener etc.) |

| Curing type | Pressurize steam | Natural (water) curing |

| Curing period | 12 Hours | 10 Days minimum |

| Compressive strength and water absorption percentage are related to density. | ||

Advantages of Aerated Lightweight Concrete Bricks - AAC and ALC/NAAC

- Reduction of steel & cement requirement in structure due to less weight of wall results in savings up to 15% of total project cost.

- Facilitates construction of unplanned walls anywhere & anytime.

- Weighing approx ⅓ rd than clay or fly ash bricks and blocks have an average compressive strength >2.5 N/mm2

- Thermal insulation performance is far better than clay bricks & RCC

- With a just 100 mm thickness of wall 700 Kg/M3, aerated lightweight concrete Bricks offers fire endurance for heat transmission for Long hours.

- Water absorption of aerated lightweight brick is relatively lower compared to conventional bricks. It is < 25 % for a density of 700 kg/m3.

- Closed cell structure of aerated lightweight concrete bricks reduces water absorption, So, no more damp spots on the wall.

- Lower water absorption property of these blocks will help to reduce cracks in walls

- The lightness of the material increases resistance against earthquakes

- Due to cellular structure, it gives better sound insulation

- It is ideal for any construction like houses, apartments, commercial constructions, schools, hospitals and amphitheaters. Etc.

- Less electricity required for AC/Heater Due to Good thermal Insulation Property

- Least energy requirement on production

- Aerated lightweight concrete bricks are manufactured with fly ash - 100% recycled resource

- Valuable soil is not consumed

- Very less energy is used for manufacturing

- Compressive strength increases with age of ALC/NAAC Blocks

- Typical Life is approximately double than clay bricks

- Due to less weight & larger size its economical in transportation and handling

- Significant reduction of overall weight results in savings on structural frames, footings or piles (steel and cement).

- Lesser joints and accurate dimensions of blocks, reduces mortar, plastering and precious time of labor resulting in huge savings

- The bricks can be sawed, drilled and shaped like wood using standard hand tools, regular screws and nails. It is simpler than brick or concrete. so less wastage

- By using a 6 inch block in place of 9 inch brick, customers get an additional 2% - 3% carpet area. This savings on account of additional carpet area gained is more than cost of bricks

- Savings in overall construction cost can be up to 15% when using aerated lightweight concrete blocks, as compared to clay bricks after considering the resulting savings in steel, structure, cement, sand, gravel and time etc