- Aerated (AAC/ALC) Block Characteristics

- Difference Between AAC & ALC

- Difference between CLC and ALC

- Project Information - Is it worth starting

- ALC Manufacturing Process, Raw Material & Mix Ratios

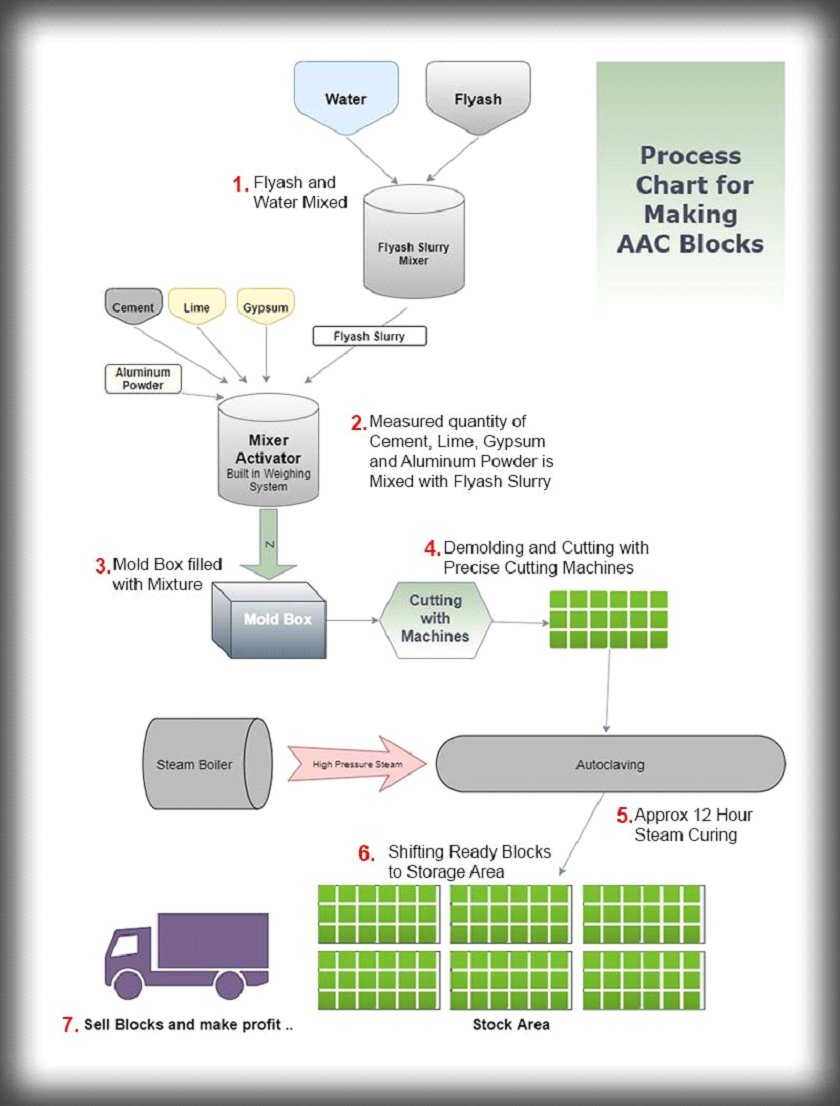

- AAC Manufacturing process, Raw Material & Mix Ratios

- 10 Reasons to Choose Essarcon

- FAQ - Frequently Asked Questions

RAW MATERIALS AND RECIPE TO PRODUCE AUTOCLAVED AERATED CONCRETE (AAC)

Main ingredients (Raw Materials)

Water

Water for concrete mixture shall have any suitable drinking water. It is preferable to water from surface sources, unsalted, soft or medium hardness. It is also preferred to provide the required amount of water lukewarm/hot for best results.

Portland Cement

Virtually all of Ordinary Portland Cement (OPC 53 Grade) suitable for the production of aerated lightweight concrete. Cement should be fresh, lumps free. Preferred use of a good standard brand.

Quick lime

Quicklime is produced by heating naturally-occurring limestone rock, which contains calcium carbonate. It is recommended to use fresh quick lime. More purity provides better results.

Gypsum

Gypsum, also known as Plaster of Paris ( POP )

Fillers

As part of an autoclaved aerated concrete mix, fly ash/pond ash is used as a filler. This ash is obtained from thermal power plants (fly ash is a silica rich product, which is industrial waste obtained from thermal power plants).

Foaming Agent

Small quantity of aluminum powder is used for Foaming of concrete

Additives

Just like other concrete, additives such as activators/accelerators may be used to improve and stabilize the quality of the final product.

- Water : 200-280 Ltrs

- Ordinary portland cement : 90-110 Kg

- Quick lime : 30-50 Kg

- Gypsum - 5-10 Kg

- Fly ash : 450-550 Kg

- Aluminum powder : 400-500 gms

- Additives : Quantity depends on raw material properties

AAC Block Manufacturing Process

- Measured quantity of water is poured in the primary slurry mixer.

- Fly ash is added in the primary slurry mixer. Mixed well and checked the density of slurry. To obtain the desired density, it needs to add more water or fly ash.

- Pour desired quantity of prepared slurry into the main mixer.

- Desired quantity of cement is mixed with fly ash (filler) slurry.

- Measured quantity of lime is added into the mix.

- Measured quantity of gypsum is added into the mix.

- Additives (if required) are poured in the mixer.

- MIxture is heated to 40-45 °C with the help of steam.

- Aluminum powder premixed with a small quantity of water is added in the mixer.

- After mixing for about 30 seconds, Prepared concrete slurry is poured in lubricated molds.

- After filling the mold, the mold moves towards pre pre-curing area and a new mold moves towards the mixer for the next fill.

- In filled mold, Concrete slurry rises (just like Bread dough) and volume increases up to desired height in 15-20 Minutes.

- After 3-5 Hrs. raised concrete gets its initial strength and mold panels are removed for the cutting process.This demolding process may be manual or with the help of a demolding machine.

- Then this concrete “cake” is sliced in required sizes Horizontally and then Vertically with cutting machines.

- After cutting these sliced cakes on mold trolleys, these mold trolleys are parked in the waiting area.

- When the autoclave is ready, these trolleys are inserted into the autoclave for steam curing.

- After closing the autoclave door securely, Boiler generated steam is fed to the autoclave through a pipeline in a controlled manner

- Autoclaving (Steam curing) cycle:

- Charging phase: Feeding steam and increasing pressure up to 12 Kg

- Holding Phase: Maintaining pressure around 12 Kg for 5-6 Hours

- Releasing steam and reducing pressure to null

- After curing is completed, mold trolleys are removed from the autoclave and cured blocks are shifted to the stockyard.

- Once moisture is released from blocks, these are ready to ship.