Redefining AAC/ALC Block Machinery for a Competitive Edge

Traditionally, AAC/ALC block machinery focused solely on production. But to stand out in today's competitive market, AAC/ALC block manufacturers need to consider next-generation superior machinery that goes beyond just making blocks. Here's a redesigned approach:

Focused on Efficiency and Automation:

- Multi-size and multi-profile capabilities:

We produce a wider variety of AAC/ALC block plants to cater to diverse production needs. - Modular design:

Allow for easy expansion and configuration changes to adapt to future production needs. - PLC Based control systems:

Real-time production monitoring and control systems - High-speed batching-mixing systems:

Reduce cycle times and increased output - Autoclave optimization with steam savings:

Reduce steam requirements and energy consumption while maintaining block quality. - Advanced mold demolding systems:

Integrated tilting and demolding in a single machine for a more sustainable production process.

The Competitive Advantage:

By incorporating these elements, AAC/ALC block machinery can become a strategic tool for businesses. It can deliver:

- Increased production capacity and reduced costs.

- Enhanced product quality and consistency.

- Greater flexibility and responsiveness to market needs.

- Improved sustainability through resource optimization.

Remember:

Remember:

The most competitive AAC/ALC block machinery solution will be one that is tailored to address your company's specific challenges and growth goals.

Click here for more on AAC Block Manufacturing Plant Setup Cost in India

Minimizing Downtime for Maximum AAC/ALC Block Production

Downtime is the enemy of production. Here's how redesigned AAC/ALC block machinery can be engineered to specifically target downtime reduction:

Improved Equipment Reliability:

- Heavy-duty and wear-resistant components:

Invest in machinery built with durable materials to minimize repairs and replacements. - Simplified and accessible design:

Ensure easy access to machine components for maintenance and cleaning tasks. - Standardized spare parts:

Facilitate quick replacement of parts when necessary, reducing downtime for sourcing components.

Enhanced Operator Training and Support:

- Advanced operator training programs:

Train operators on proper equipment use, basic troubleshooting, and preventive maintenance procedures. - Dedicated technical support:

Provide access to qualified technicians for prompt assistance in case of complex issues. - Improved maintenance efficiency.

By incorporating these features, AAC/ALC block machinery can significantly reduce downtime through:

- Reduced number of unexpected equipment failures.

- Faster identification and resolution of potential problems.

- Improved maintenance efficiency.

This product is for the new start ups and who are new to this industry. Or say someone wants to produce blocks in a brand new market with minimum risk of investment.

Small plants are for small production with low investment.

It starts from 3.3M³ and reaches a maximum of 26M³ per Day.

These lines are compatible with natural curing

An ideal production line with a perfect combination of Performance and Budget

It starts from 8.6M³ and reaches a maximum of 80M³ per Day.

These are categories in two types :

- Stationary type Mold system - ACB Pro - FX ( called Stationary line ) the molds do not move, for pouring, and cutting, the mixer and cutting machines move along the rails.

Advantages :

- Easy to install

- Can be upgrade to conveyor line

- Movable type Mold system - ACB Pro - TT ( called Conveyor line ) In conveyor lines, molds move along the rails, and the mixer and cutting machines stand still.

Advantages :

- Easy to automate

- The area of the room is saved due to the proximity of the forms High productivity

These lines are compatible with natural curing (ALC) as well as steam curing (AAC).

From Startup to Success: Your AAC Block Production Partner

Essarcon doesn't just provide AAC block plants – we empower your business. Regardless of your plant size, we offer comprehensive support at every stage:

Our expertise ensures you produce high-quality AAC blocks and navigate the production process with confidence

Benefits:

We manufacture AAC block plants catering to various production scales and budgets.

- Starter-Friendly: Our SU Series targets beginners by providing a cost-effective entry point into AAC block production.

- Budget-Conscious: The Eco Series focuses on affordability with essential equipment, keeping initial investment low. It also allows for future upgrades as your business grows.

- High-Performance: The Pro Series caters to established businesses, featuring advanced automation for maximum efficiency and high-volume AAC block production.

Production Lines

ALC Mini

LineALC Pro TT

Conveyor LineALC Pro FX

Stationary LineALC & AAC

Hybrid LineAAC SU

SeriesAAC Eco

SeriesAAC Pro

Series

ACB Mini Eco - 3

ACB Mini - 6

Description

Stationary line for the production of aerated concrete - ACB Mini series with a capacity of up to 26M³ per day. The line consists of a mobile mini mixer-activator suitable for a batch volume of 0.33 M³, Lower height of feeding hopper for easy material feeding in the mixer. Semi automatic cutting machine capable of Six surface cutting, stationary mold base frames interconnected with rail track, mold boxes. transfer trolley with its track

Key features

- Mobile mini mixer activator equipped with Load cell based material weighing system

- L shape openable mold boxes equipped with toggle clamps for easy de-molding

- Semi automatic mobile cutting system with Six surface finish

- Mobile semi automatic cutting system with Six surface finish

- Easy to operate machines

Mold dimensions : 600W x 230H x 2400L

No. of Bricks per Mold

100W x 230(or 200)H x 600L = 24Pcs

150W x 230(or 200)H x 600L = 16Pcs

200W x 230(or 200)H x 600L = 12Pcs

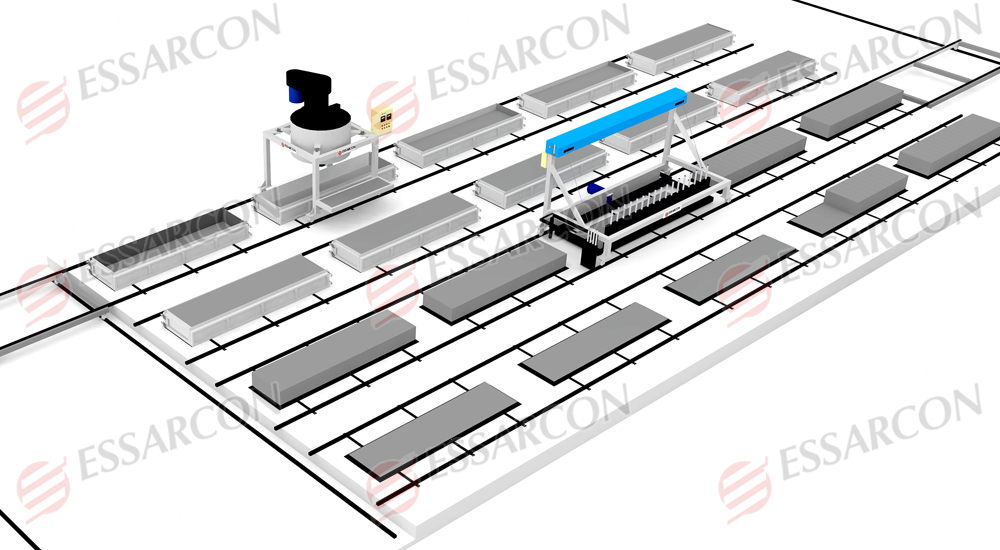

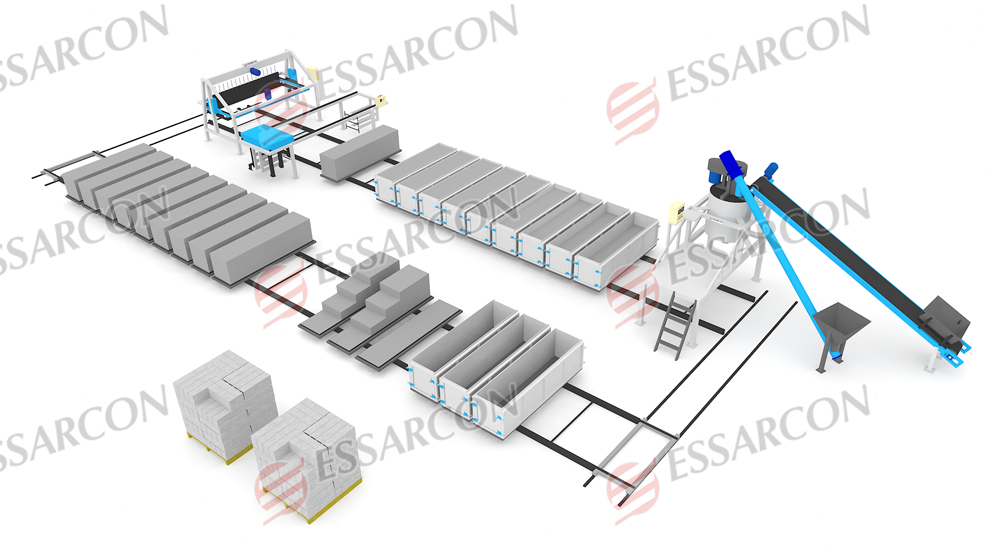

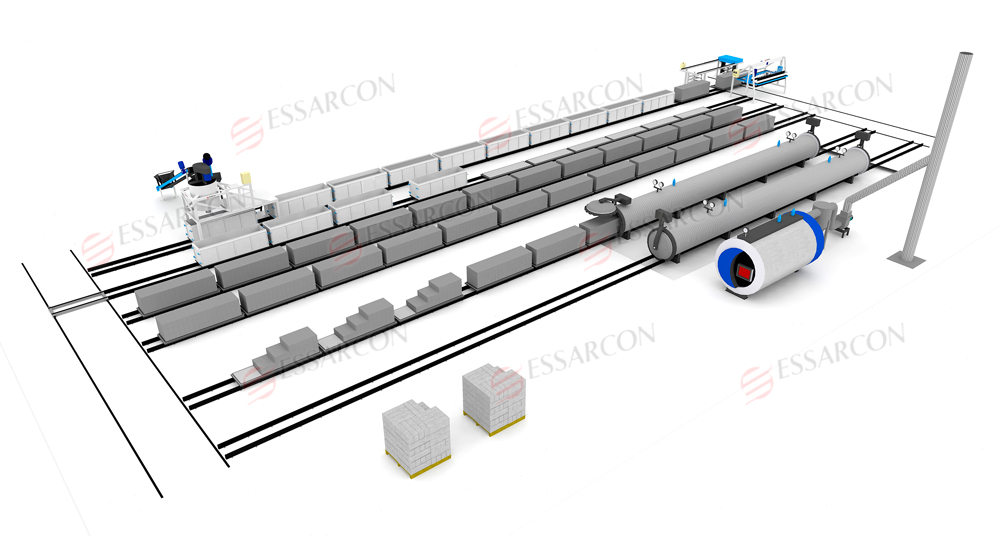

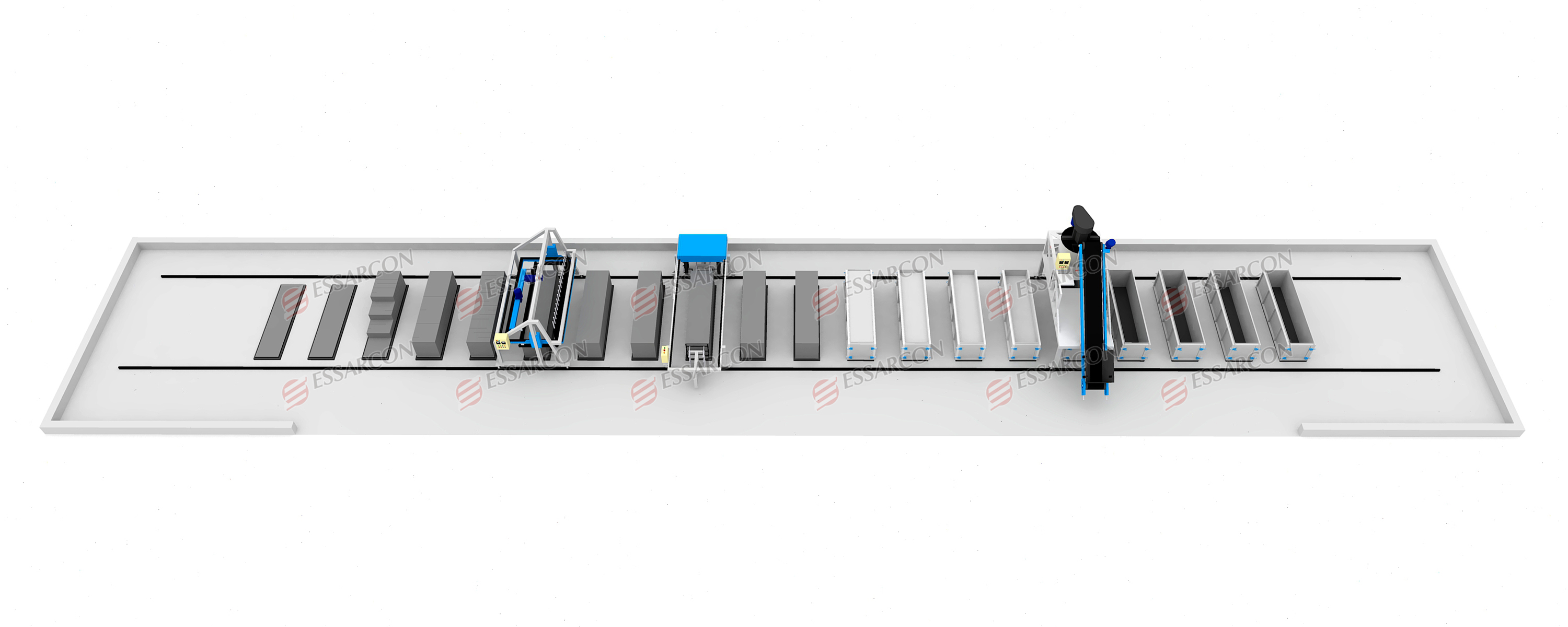

Layout of Plant

ACB Pro TT - 42

ACB Pro TT - 17

ACB Pro TT Eco - 9

Description

Conveyor line for the production of aerated concrete - ACB Pro TT series with a capacity of up to 80M³ per day. The standard line consists of a fixed mixer-activator suitable for a batch volume of 0.86 M³, automatic material feeding system includes screw conveyor for cement and belt conveyor for fly ash (optional in Eco Model), Automated cutting system includes Horizontal cutting machine and Vertical cutting machine, mobile mold base trolleys, mold boxes, rail tracks, transfer trolleys with its track. Optionally, the line can be equipped with a cement and fly ash silo.

Key features

- Stationary mixer activator with Load cell based automatic batching control

- Screw conveyor for cement feeding (optional in Eco Model)

- Belt conveyor for fly ash feeding (optional in Eco Model)

- Four side openable mold boxes equipped with toggle clamps for easy de-molding

- Heavy mold base trolleys fitted with specially designed wheels for easy movement

- Automatic cutting system with Six surface finish

- Easy to increase productivity

Can be converted to AAC/ALC by adding an autoclave and boiler.

Mold dimensions : 600W x 600H x 2400L

No. of Bricks per Mold :

100W x 200H x 600L = 72Pcs

150W x 200H x 600L = 48Pcs

200W x 200H x 600L = 36Pcs

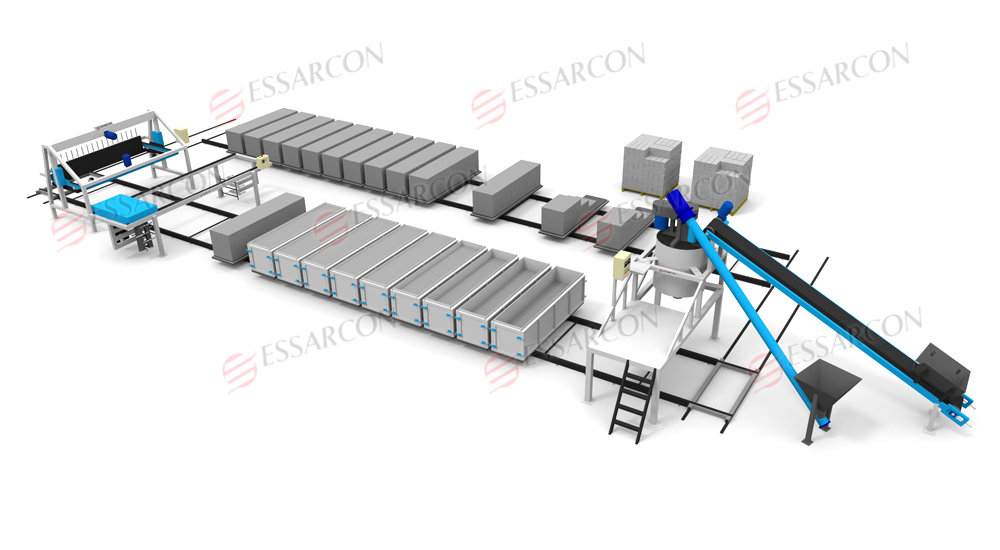

Layout of Plant

ACB Pro FX - 17

ACB Pro FX Eco - 9

Description

Stationary line for the production of aerated concrete - ACB Pro FX series with a capacity of up to 43M³ per day. The line consists of a mobile mixer-activator suitable for a batch volume of 0.86 M³, Raw material feeding belt conveyor (Optional with Eco Model) , Automated cutting system includes mobile Horizontal cutting machine and mobile Vertical cutting machine, stationary mold base frames interconnected with rail track, mold boxes.

Key features

- Mobile mixer activator equipped with Load cell based material weighing system

- Optional belt conveyor for raw materials feeding

- Four side openable mold boxes equipped with toggle clamps for easy de-molding

- Stationary mold base frames interconnected with rail track

- Mobile automatic cutting system with Six surface finish

Can be converted to AAC/ALC by adding an autoclave and boiler along with mobile mold base trolleys.

Mold dimensions : 600W x 600H x 2400L

No. of Bricks per Mold :

100W x 200H x 600L = 72Pcs

150W x 200H x 600L = 48Pcs

200W x 200H x 600L = 36Pcs

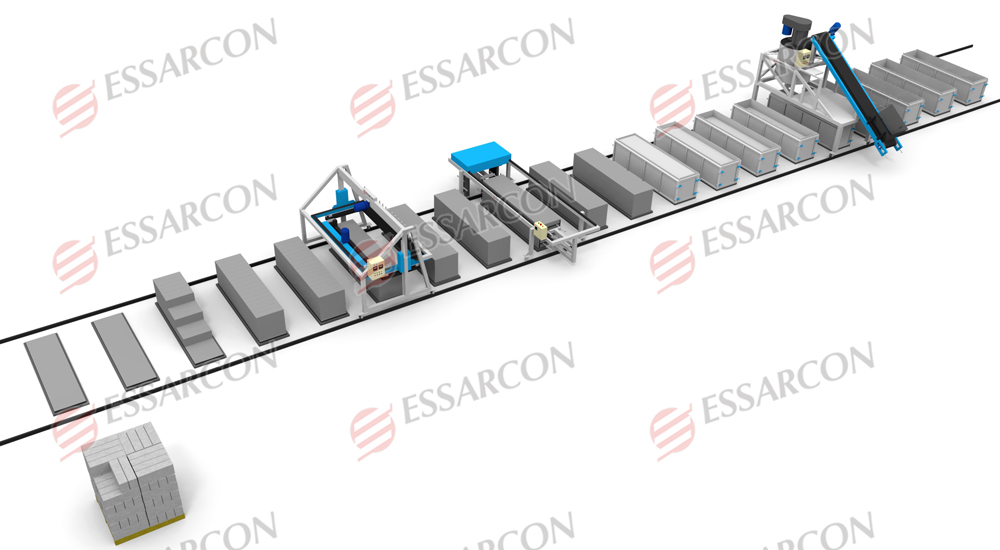

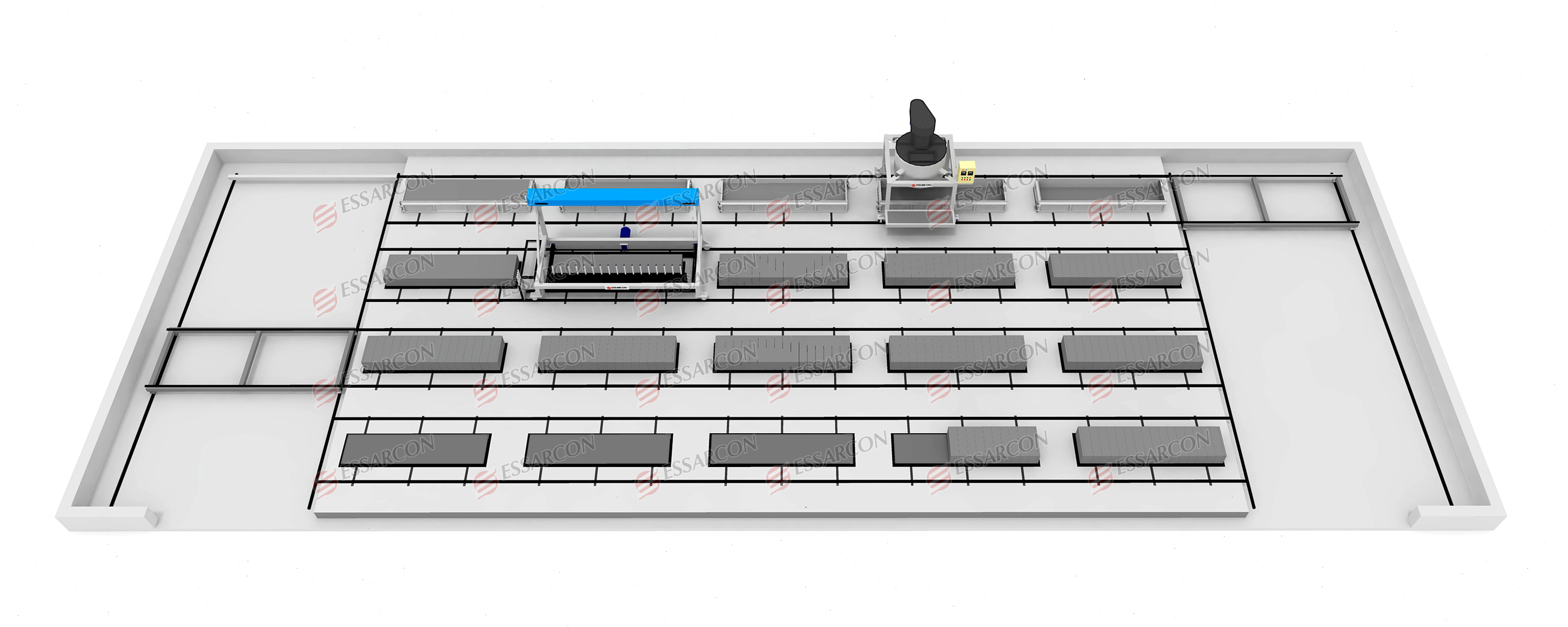

Layout of Plant

AAC-ALC Hybrid 17

Description

This system is designed to produce AAC as well ALC blocks in same plant. Machines are similar to ALC Line - ACB Pro TT. Mold volume is 0.86M³. 3 Layers of blocks in each mold. One can use autoclave and boiler to produce AAC blocks to cater the clients demanding AAC only. Simultaneously ALC Blocks are produced for other clients. This enables the optimum use of system and produces more blocks to reduce the payback period.

Simplest system for AAC & ALC production made ever. The line consists of a mixer-activator suitable for a batch volume of 0.86M³, raw material feeding belt conveyor, automated cutting system includes Horizontal cutting machine and Vertical cutting machine, mobile mold base trolleys, mold boxes, rail tracks, transfer trolleys with its track, curing autoclave and a boiler.

Key features

- Stationary mixer activator with Load cell based automatic batching control Screw conveyor and Belt conveyor for raw materials feeding.

- Four side open able mold boxes equipped with toggle clamps for easy de-molding,

- Heavy mold base trolleys fitted with specially designed wheels for easy movement

- Automatic cutting system with Six surface finish

- Curing autoclave included

- Productivity of AAC/ALC can be expanded by adding more autoclave and molds

- Productivity of ALC can be expanded by more molds.

- Modular system for quick add-ons of many accessories to ease the operations and increase the productivity.

Mold dimensions (Finished cake): 600W x 600H x 2400L

No. of Bricks per Mold :

100W x 200H x 600L = 72Pcs

150W x 200H x 600L = 48Pcs

Production capacity: AAC/ALC up to 8.6M³ /Day + ALC up to 8.6M³ /Day can be expand up to 80M³ /Day in total

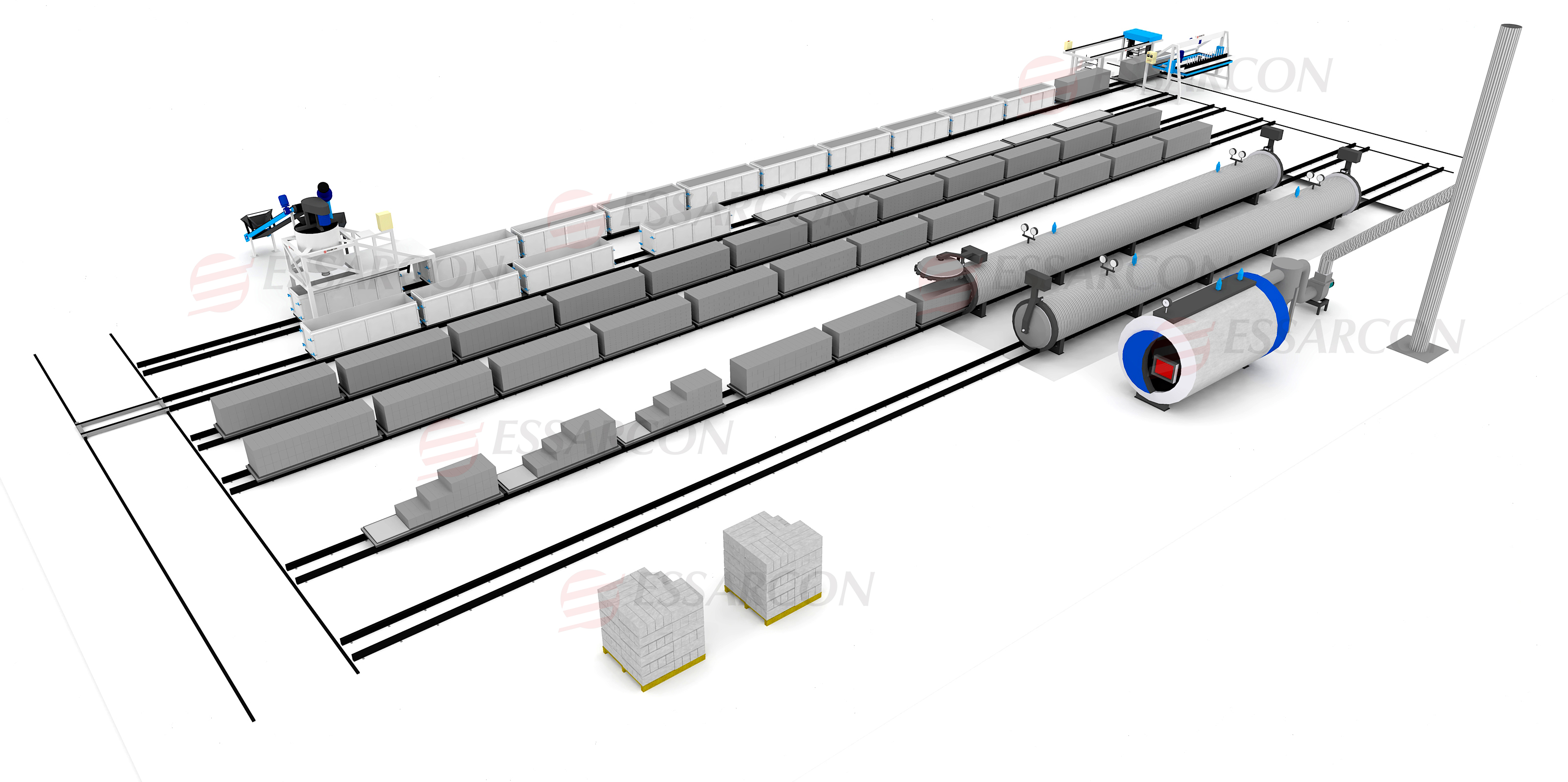

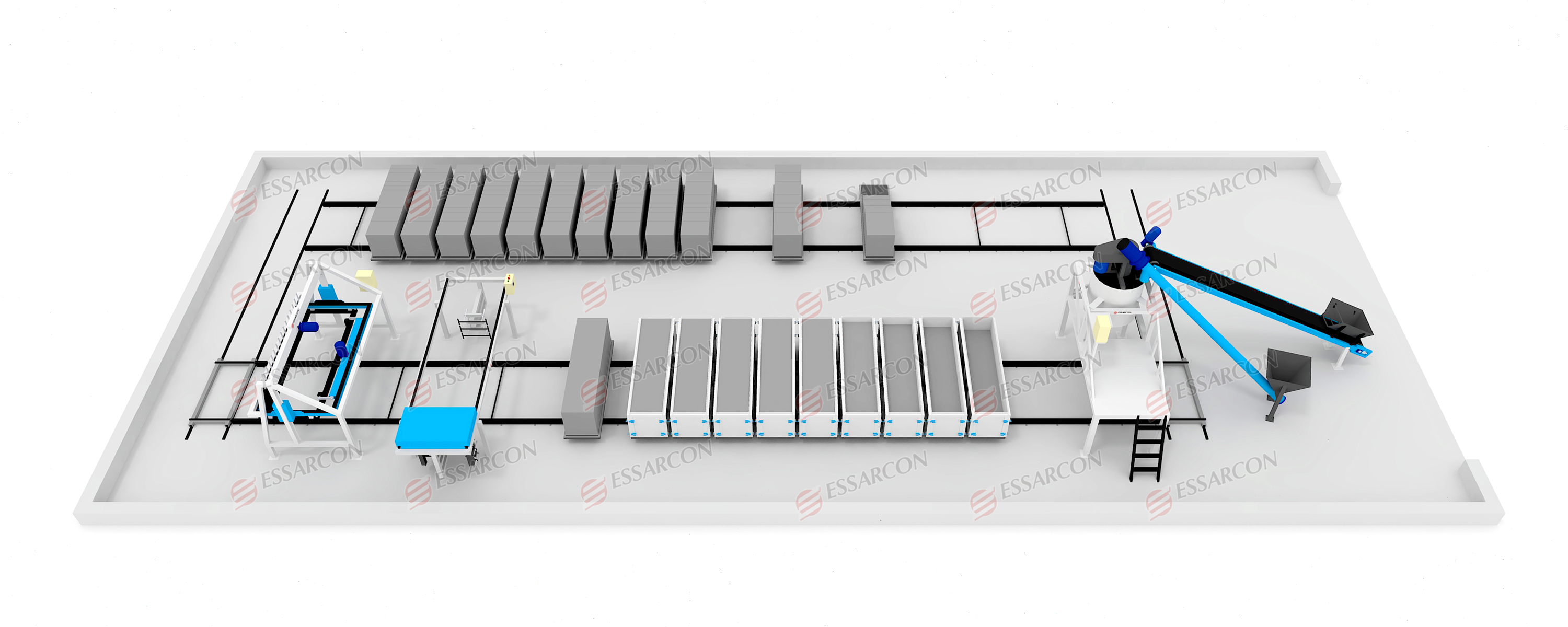

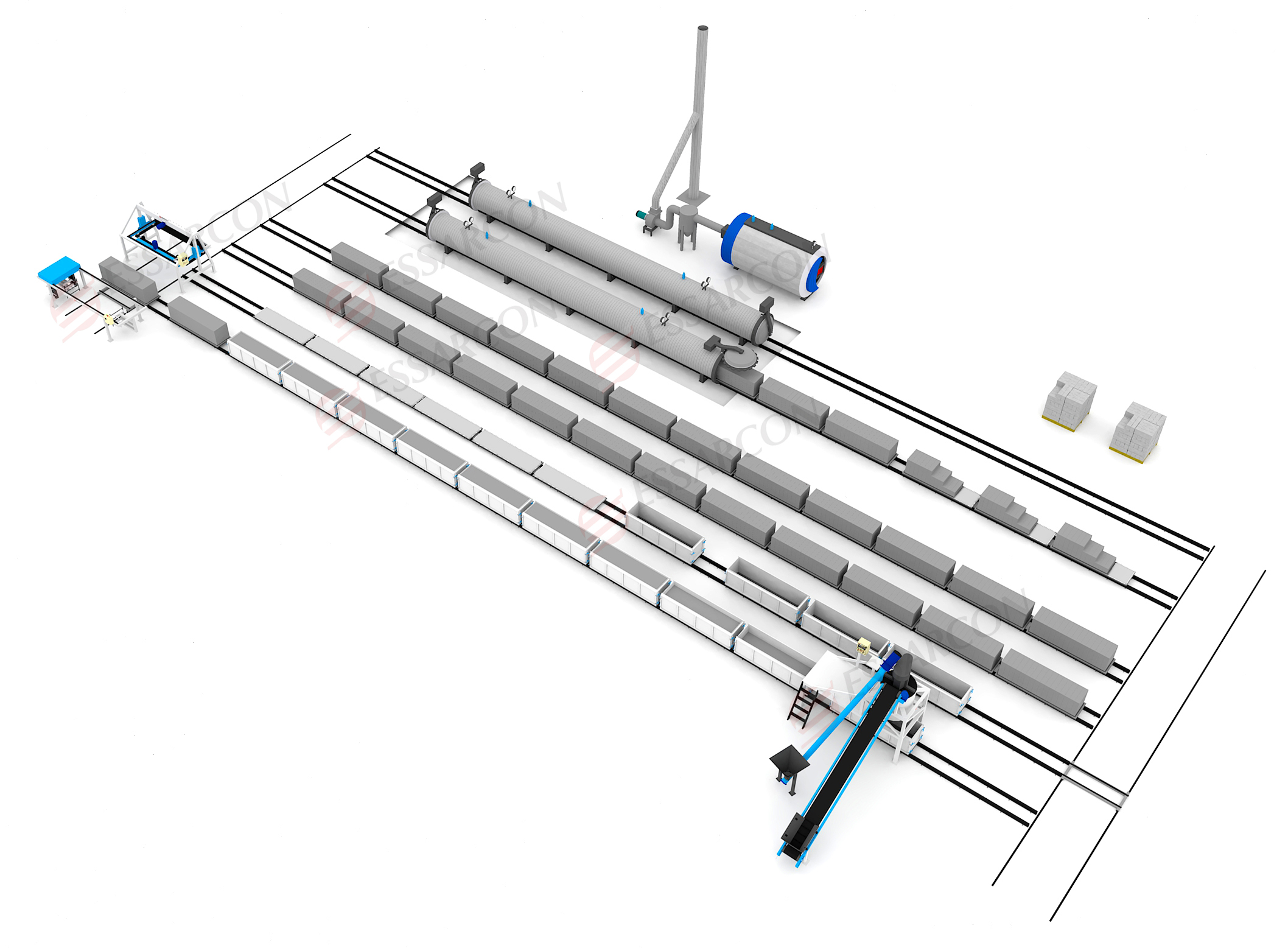

Layout of Plant

Description

The AAC Startup Series offers a comprehensive solution for entrepreneurs looking to start AAC block production with minimal investment. This small-scale plant includes all the necessary equipment from the ACB Pro series (ALC block production line), along with an autoclave and boiler. The modular design allows for a gradual expansion of production capacity, starting with ALC blocks and seamlessly transitioning to AAC blocks in the future.

One of the key advantages of AAC block production is the elimination of the natural curing process, significantly reducing production time. Additionally, the cost of producing AAC blocks decreases as production volume increases, making it a more economically viable option compared to ALC. This makes the AAC Startup Series an attractive choice for startups seeking to enter the AAC block market with a flexible and scalable solution.

Despite being designed for startups, this line is capable of producing up to 86 cubic meters of AAC blocks per day

Benefits

- Minimal Investment Start: Can begin producing ALC blocks with a smaller initial investment.

- Gradual Expansion: Expand production capacity step-by-step as your business grows.

- Seamless Upgrade: Easily transition to AAC blocks production in the future by adding autoclaves and a boiler.

- Scalability: Increase productivity further by adding more molds and autoclaves.

- Dual Production: Produce both ALC and AAC blocks simultaneously, catering to diverse market demands.

Key features

- Mold volume (Finished cake) approximate 0.86M³

- High speed mixer activator with Load cell based automatic batching control

- Fly ash Slurry preparation mixer

- Belt conveyor for raw materials feeding to mixer

- Heavy mold base trolleys fitted with specially designed wheels for easy movement

- Automatic cutting system with Six surface finish

- Curing autoclave included

Mold dimensions: 600W x 600H x 2400L

No. of Bricks per Mold :

100W x 200H x 600L = 72Pcs.

150W x 200H x 600L = 48Pcs.

200W x 200H x 600L = 36Pcs.

Production capacity: up to 86M³/Day

Mold volume is 0.86M³ and offers 3 Layers of blocks in each mold.

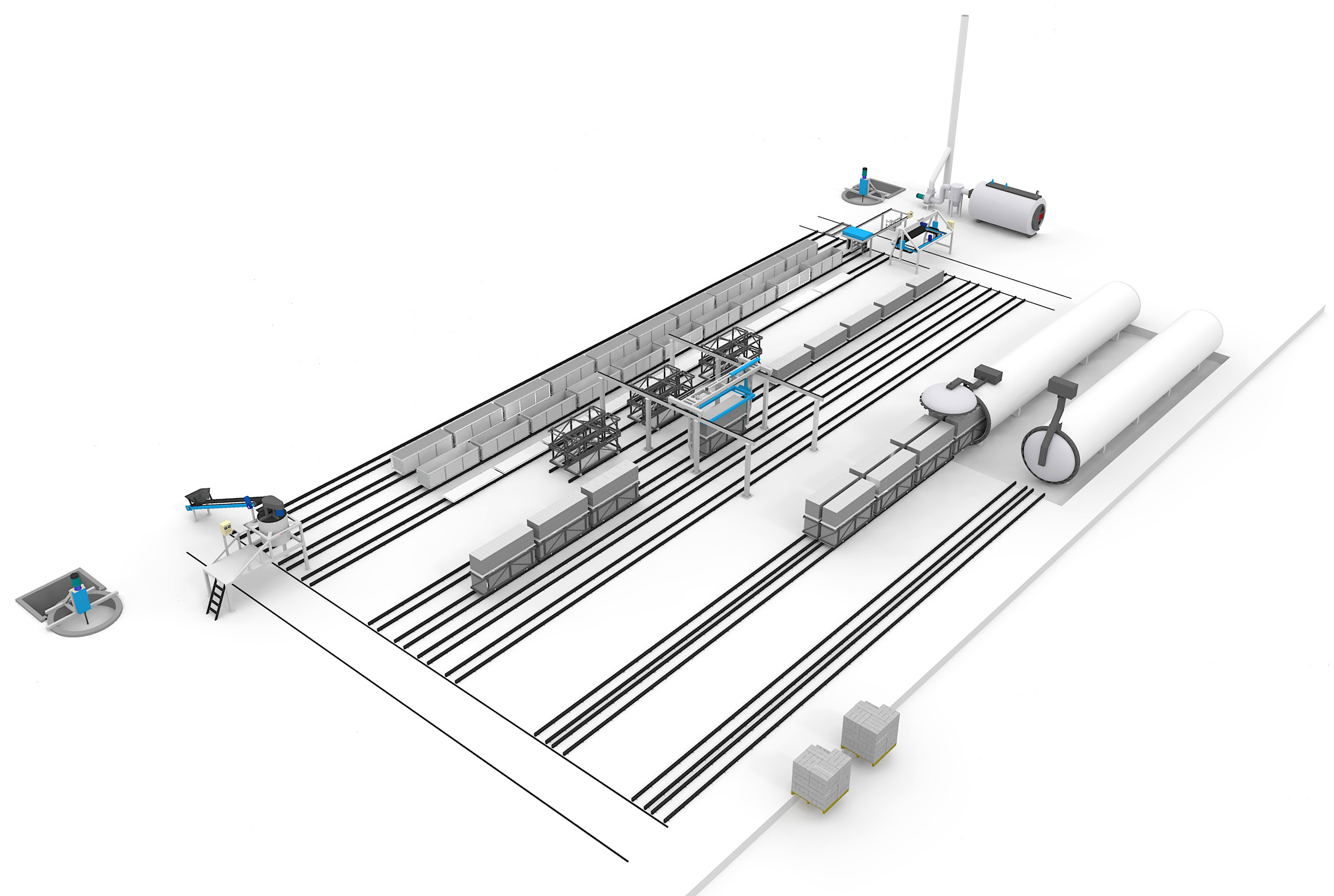

Layout of Plant

Description

This is an Ideal startup AAC/ALC plant designed to cater the requirements of today’s competition world. This includes a Hi speed mixer equipped with load cell based material weighing system. PLC based easy to operate control panel for batching and mixing. Raw material feeding belt conveyor, Unique Automated cutting systems includes tilting - demolding machine, horizontal cutting machine and vertical cutting machine & autoclave. Buyers can purchase a boiler on their own locally, otherwise we can supply from our ventured manufacturers.

Key features

- Mold volume (Finished cake) approximate 1.3M³

- Mixer activator with Load cell based batching control

- Fly ash Slurry preparation mixer

- Belt conveyor for raw materials feeding

- Tilting mold boxes - Tilting provides consistent density

- Heavy mold base trolleys fitted with specially designed wheels for easy movement

- Automatic 2 stage cutting system with Six surface finish

- Curing autoclave included which is capable to cure molds with 6 layers of block on dual track - This save up to 20% of steam cost than conventional method

Mold dimensions: 600W x 1200H x 1800L

No. of Bricks per Mold :

100W x 200H x 600L = 108Pcs.

150W x 200H x 600L = 72Pcs.

200W x 200H x 600L = 54Pcs

Production capacity: up to 105M³ /Day

Mold volume is 1.3M³ and offers 6 Layers of blocks in each mold.

Description

Performance is a key to productivity. High speed mixer fitted with automatic batching hopper system with dedicated cement and lime feeding screw conveyors, integrated aluminum powder mixer-dispenser. PLC based control panel is included for easy operations. Features underground slurry mixers for both fresh and recycled fly ash slurry preparation. Includes a unique tilting-demolding system for faster operations. Optional Silos for raw material storage. This is a high performance more automated line.

Key features

- Mold volume (Finished cake) approximate 1.3M³

- Mixer activator is equipped with additional batching hoppers for speedy raw material weighing.

- Two screw conveyors, each one is for cement and lime feeding

- Two slurry preparation mixers. Each one is for Fresh and recycled slurry

- Tilting mold boxes - Tilting provides consistent density and faster production

- Heavy mold base trolleys fitted with specially designed wheels for easy movement

- Automatic 2 stage cutting system with Six surface finish

- Curing autoclave included which is capable to cure molds with 6 layers of block on dual track - This save up to 20% of steam cost than conventional method.

Mold dimensions: 600W x 1200H x 1800L

No. of Bricks per Mold :

100W x 200H x 600L = 108Pcs.

150W x 200H x 600L = 72Pcs.

200W x 200H x 600L = 54Pcs.

Adding more autoclaves and molds will increase the production

Production capacity: up to 125M³ /Day

Mold volume is 1.3M³ and offers 6 Layers of blocks in each mold.